Low battery

Battery level is below 20%. Connect charger soon.

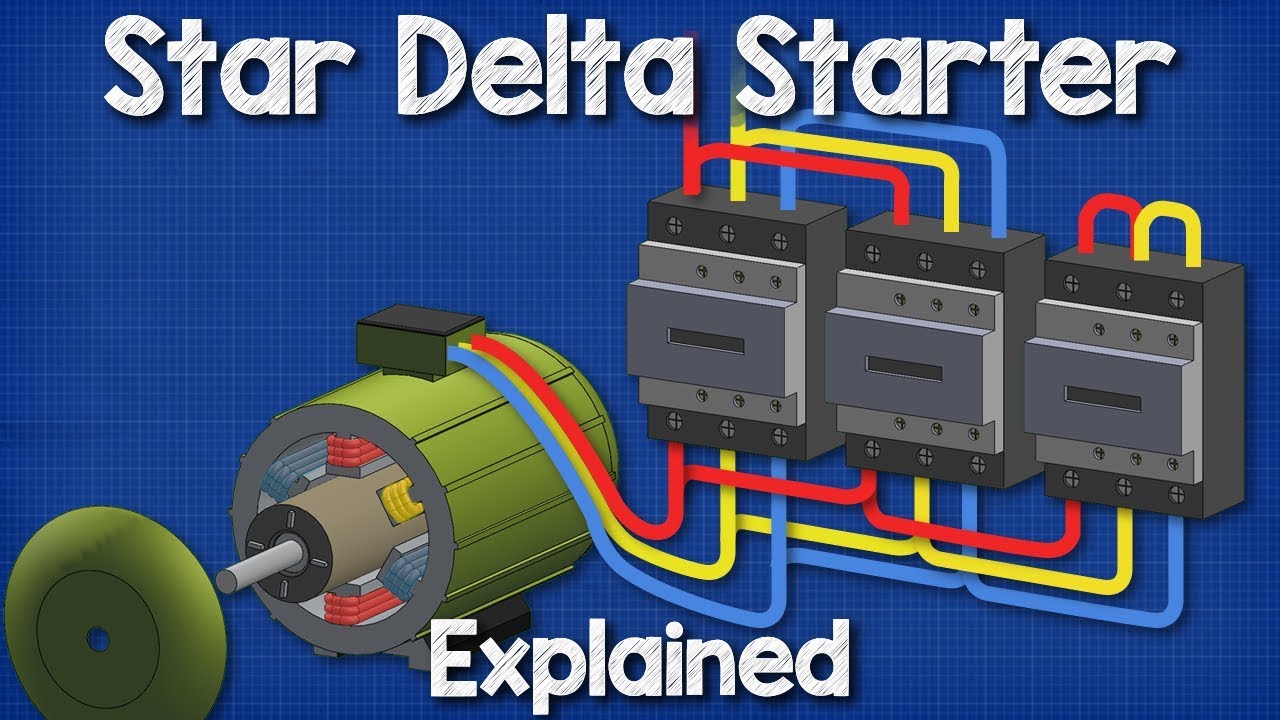

Close Transition Star Delta Starter: How It Works and Why It Matters

Electric motors are the workhorses of modern industry, powering everything from pumps and compressors to conveyor belts and manufacturing equipment. However, starting these motors can be a significant challenge. Large motors, particularly, can draw excessive current during startup, leading to voltage dips, potential damage, and hefty electricity bills. This is where the close transition star delta starter comes into play. This article delves into the intricacies of this crucial motor starting method, explaining its operation, benefits, and why it’s a preferred choice in various applications.

Understanding the Problem: High Inrush Current

Before we explore the solution, let’s understand the problem. When a large induction motor is started directly online (DOL), it acts like a transformer with a shorted secondary. This results in a surge of current, known as inrush current, that can be 5 to 7 times the motor’s rated full-load current. This massive inrush can:

- Cause voltage dips: These dips can affect other equipment connected to the same power supply, causing them to malfunction or even shut down.

- Damage the motor: Excessive current can overheat the motor windings, shortening their lifespan.

- Trigger protective devices: Circuit breakers and fuses might trip, interrupting operations.

- Increase electricity costs: High inrush current translates to higher energy consumption during startup.

The Solution: Close Transition Star Delta Starting

The close transition star delta starter is a type of reduced voltage starter designed to mitigate the detrimental effects of high inrush current. It achieves this by starting the motor in a star configuration and then smoothly transitioning to a delta configuration once the motor reaches a significant speed.

How it Works: A Step-by-Step Breakdown

Here’s a detailed explanation of the close transition star delta starting process:

Star Configuration (Starting Phase): Initially, the motor windings are connected in a star configuration. This effectively reduces the voltage applied to each winding by a factor of √3 (approximately 0.58 of the line voltage). Consequently, the starting current is significantly reduced (to about 1/3rd of the DOL current).

Ramp-Up and Monitoring: The motor accelerates under the reduced voltage. The starter continuously monitors the motor’s speed or current.

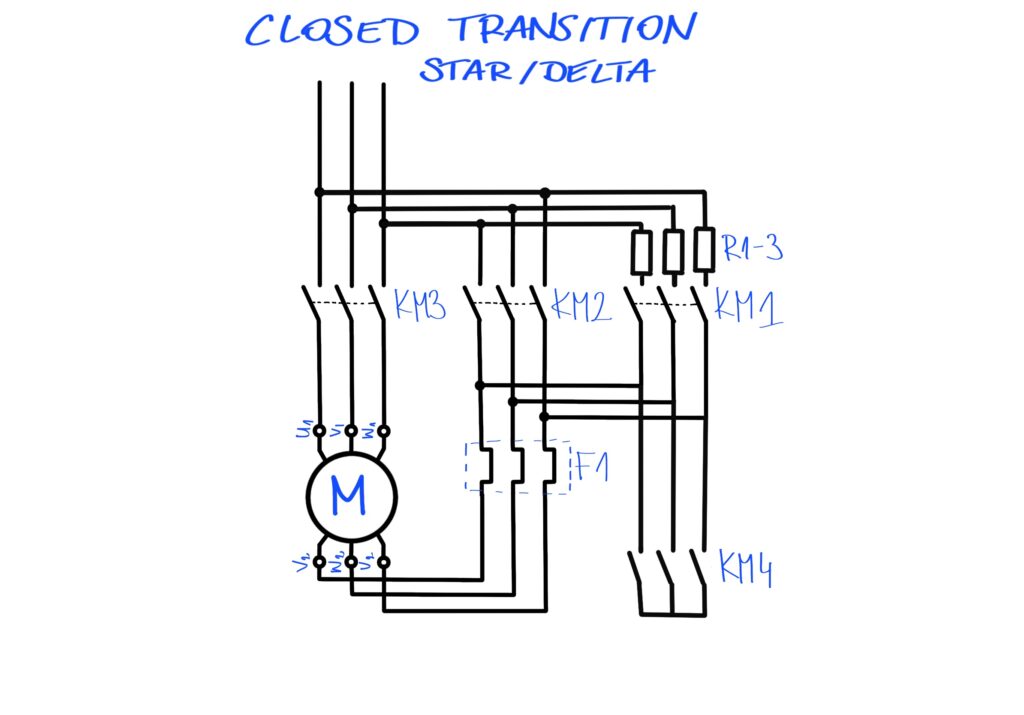

Transition Phase (Close Transition): Once the motor reaches a predetermined speed (typically around 70-80% of its rated speed), the starter initiates the crucial transition. The close transition distinguishes this method. Instead of simply opening the star contactor and closing the delta contactor (which would create an open transition and a brief period with no power), the close transition maintains power continuity. This is achieved by:

- Short-Circuiting the Motor: The star connection is momentarily short-circuited, maintaining power to the motor.

- Delta Connection: The motor windings are then connected in a delta configuration. This applies full line voltage.

Delta Configuration (Running Phase): The motor now operates in the delta configuration at its rated voltage.

Advantages of Close Transition Star Delta Starters

Compared to other starting methods, the close transition star delta starter offers several advantages:

- Reduced Starting Current: Significantly lower inrush current compared to DOL starting, minimizing voltage dips and strain on the power supply.

- Smoother Transition: The “close transition” feature ensures a seamless switch from star to delta, preventing the motor from experiencing a complete power loss during the transition. This is crucial for applications requiring continuous operation.

- Cost-Effectiveness: Generally, a more economical solution compared to variable frequency drives (VFDs) for reducing starting current.

- Simplicity and Reliability: Relatively simple design, making them robust and less prone to failure compared to more complex starting methods.

- Extended Motor Life: Reduced stress on motor windings due to lower starting current, prolonging the motor’s lifespan.

Applications of Close Transition Star Delta Starters

These starters are ideal for a wide range of applications, including:

- Pumps: Water pumps, sewage pumps, and industrial process pumps.

- Compressors: Air compressors and refrigeration compressors.

- Fans: Large industrial fans and ventilation systems.

- Conveyor Systems: Material handling and assembly lines.

- Crushers and Grinders: Used in mining and processing industries.

Key Components of a Close Transition Star Delta Starter

The essential components of a close transition star delta starter typically include:

- Three Contactors: One for star connection, one for delta connection, and one for the line supply.

- Overload Protection: To protect the motor from overload conditions.

- Timer: To control the transition time from star to delta.

- Control Circuit: Including relays and other components to manage the switching sequence.

- Fuses or Circuit Breakers: For short-circuit protection.

Why Close Transition Matters: Preventing Power Interruptions

The crucial differentiator of a “close transition” star delta starter is its ability to maintain power continuity during the transition from star to delta. This feature prevents:

- Momentary Power Loss: An open transition can briefly cut power to the motor, causing it to slow down or even stop, which is undesirable in many industrial processes.

- Reduced Process Efficiency: Interrupted operation leads to reduced productivity and potential disruptions.

- Potential for Overcurrent: Although brief, an open transition can cause a sudden current surge when the delta contactor closes.

Conclusion

The close transition star delta starter is a reliable and efficient solution for mitigating the challenges associated with starting large induction motors. By reducing inrush current, ensuring a smooth transition, and offering a cost-effective alternative to more complex methods, it protects both the motor and the power supply. Its widespread use across various industries highlights its importance in ensuring efficient and reliable operation of critical equipment. Understanding its operation and advantages is vital for engineers and technicians involved in motor control and power distribution.

Frequently Asked Questions (FAQs)

What is the difference between a close transition and an open transition star delta starter?

The key difference is the transition process. A close transition starter maintains power to the motor during the switch from star to delta by momentarily short-circuiting the motor windings. An open transition starter completely disconnects the motor from the power supply during the transition.

When should I choose a close transition star delta starter over a DOL starter?

You should choose a close transition star delta starter when starting current needs to be limited to avoid voltage dips, protect the motor, and comply with utility regulations. DOL starters are only suitable for smaller motors where starting current is not a significant concern.

What are the limitations of a star delta starter?

Star delta starters are not suitable for all applications. They provide a fixed reduced voltage start, which may not be ideal for motors with high starting torque requirements. They also offer a limited degree of control compared to VFDs.

How do I select the right size of a star delta starter for my motor?

The starter’s size is determined by the motor’s full-load current, voltage, and power rating. Consult the motor nameplate and the manufacturer’s specifications to ensure the starter is properly sized for the application.

How often do the contactors in a star delta starter need to be replaced?

The lifespan of the contactors depends on factors such as the frequency of starts and stops, load conditions, and environmental factors. Regular inspection and maintenance are crucial, and contactors may need to be replaced periodically based on wear and tear.