Low battery

Battery level is below 20%. Connect charger soon.

Meyer Plow Wiring Diagram – Fast & Easy Setup Guide

Winter’s grip brings with it the inevitable need for snow removal. For many, that means relying on a reliable snow plow, and a name synonymous with quality in the snow removal industry is Meyer. But even the best plow is useless without a properly functioning electrical system. This guide provides a comprehensive overview of the Meyer plow wiring diagram, offering a straightforward approach to ensure your plow is wired correctly and ready to tackle the toughest winter conditions. We’ll focus on making the process as clear and manageable as possible, helping you get back to clearing snow with confidence.

Understanding the Importance of the Meyer Plow Wiring Diagram

Before diving into the specifics, it’s crucial to appreciate the significance of the wiring diagram. A well-executed wiring setup is the backbone of your Meyer plow’s functionality. Incorrect wiring can lead to:

- Malfunctioning Plow: Failure to lift, angle, or lower the plow.

- Damage to Components: Blown fuses, burnt-out motors, and other costly repairs.

- Safety Hazards: Potential for short circuits and electrical fires.

- Inefficient Operation: Delays and frustrations while clearing snow.

The Meyer plow wiring diagram acts as your roadmap, guiding you through the connections and ensuring everything is wired correctly for optimal performance and safety.

Identifying Your Meyer Plow Model and Wiring Diagram

The first step is to identify your specific Meyer plow model. Different models and generations of Meyer plows utilize slightly different wiring configurations. This information is typically found:

- On the Plow Itself: Look for a model number plate, often located on the plow frame or hydraulic unit.

- In Your Owner’s Manual: The owner’s manual will contain the correct wiring diagram for your specific model. If you don’t have a physical copy, search online for your model number and “Meyer plow manual” to find a digital version.

- Online Resources: Websites like Meyer’s official website or dedicated snow plow forums often provide wiring diagrams for various models.

Once you have your model number, obtain the corresponding wiring diagram. This is your primary resource for the wiring process.

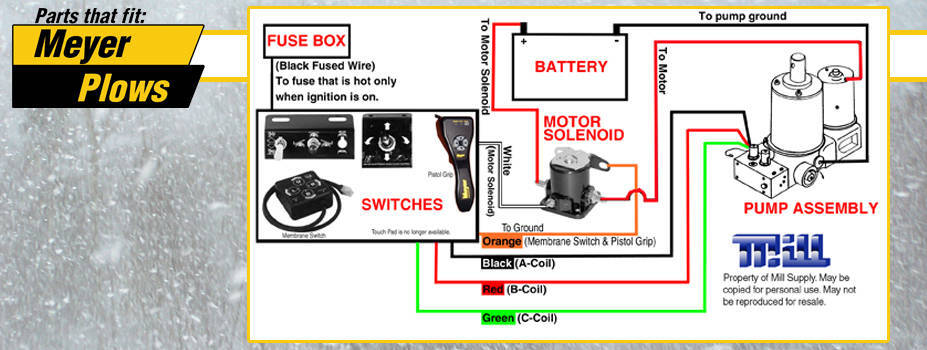

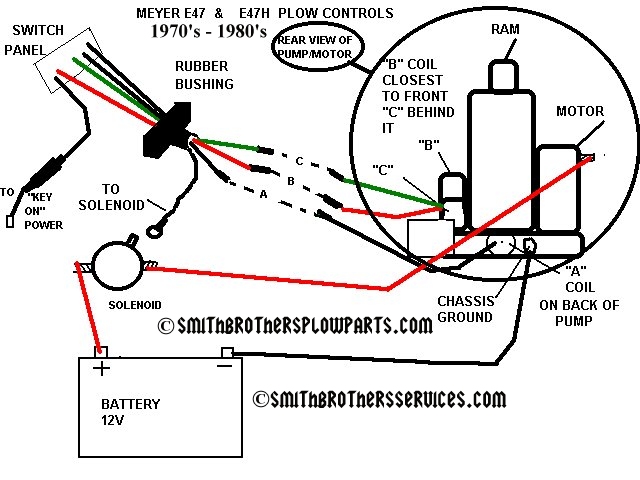

Key Components and Wiring Connections

Most Meyer plow wiring systems involve a few essential components. Understanding these elements is crucial for interpreting the wiring diagram:

- Power Source: Typically, a direct connection to the vehicle’s battery, often through a heavy-duty power cable.

- Control Unit/Relay System: This box houses relays and fuses, controlling the plow’s functions based on the operator’s commands.

- Motor: The hydraulic motor provides the power to raise, lower, and angle the plow.

- Controller (Joystick or Handheld): This device allows the operator to control the plow’s movements.

- Wiring Harness: A pre-assembled bundle of wires connecting the various components.

- Fuses: Protecting the electrical system from overcurrents.

Common Wiring Connections to Understand:

- Power (+12V) and Ground (GND): These are the primary power connections, often using thick gauge wires.

- Motor Connections: Wires connecting to the hydraulic motor for lifting, lowering, and angling. These wires often have specific polarity (positive and negative).

- Controller Connections: Wires connecting the control unit to the joystick or handheld controller.

- Fuse Connections: Protecting the circuits from overcurrent.

Following the Wiring Diagram:

- Color-Coded Wires: Wiring diagrams often use color-coded wires to identify the function of each wire. Pay close attention to these colors.

- Terminal Identification: Diagrams will indicate which wires connect to specific terminals on the relays, motor, and controller.

- Wire Gauge: The diagram will specify the appropriate wire gauge (thickness) for each connection. Use the recommended gauge for optimal performance and safety.

- Connections: Ensure all connections are secure and weather-resistant. Use appropriate connectors and consider using dielectric grease to protect against corrosion.

Step-by-Step Wiring Process (General Guide)

While the specific steps will vary depending on your Meyer plow model, here’s a general outline of the wiring process:

- Disconnect the Battery: Crucially, disconnect the negative (-) terminal of your vehicle’s battery before beginning any electrical work. This prevents accidental short circuits and potential injury.

- Mount the Control Unit/Relay Box: Securely mount the control unit/relay box in a protected location, away from direct exposure to the elements.

- Connect the Power Cable: Connect the power cable from the control unit directly to the positive (+) terminal of the battery, ensuring a secure connection. Use the appropriate fuse inline as specified in your diagram.

- Connect the Ground Wire: Connect the ground wire from the control unit to a solid ground point on the vehicle’s chassis, ensuring a clean metal-to-metal connection.

- Connect the Motor Wires: Route the wires to the hydraulic motor and connect them according to the wiring diagram. Pay attention to polarity.

- Connect the Controller: Connect the wiring harness from the control unit to your joystick or handheld controller.

- Run Wires: Route all wires neatly and securely, using wire ties or clamps to prevent them from dangling or rubbing against moving parts.

- Install Fuses: Insert the correct amperage fuses into the control unit.

- Reconnect the Battery: Reconnect the negative (-) terminal of the battery.

- Test the System: Operate the plow using the controller, verifying that all functions (lift, lower, angle) work correctly.

Troubleshooting Common Wiring Issues

Even with careful wiring, problems can arise. Here are some common issues and troubleshooting tips:

- Plow Doesn’t Lift/Lower:

- Check the fuses.

- Verify the power and ground connections.

- Inspect the motor connections for corrosion or loose wires.

- Check the controller for proper operation.

- Plow Angles in One Direction Only:

- Check the wiring to the angling cylinders.

- Inspect the controller.

- Blown Fuses:

- Identify the circuit that is causing the fuse to blow.

- Inspect the wiring for shorts or damaged insulation.

- Ensure the correct fuse amperage is being used.

- Slow Operation:

- Check the battery voltage.

- Inspect the wiring for corrosion or loose connections.

- Check the hydraulic fluid level.

Conclusion: Ensuring a Smooth Winter with a Properly Wired Meyer Plow

Wiring your Meyer plow correctly is a critical investment in your winter preparedness. By carefully following the wiring diagram, paying attention to details, and taking the time to troubleshoot any issues, you can ensure your plow operates reliably and efficiently. This guide provides the foundation for a successful wiring process, enabling you to clear snow with confidence and minimize downtime. Remember to prioritize safety and seek professional assistance if you’re uncomfortable with any part of the process.

FAQs: Meyer Plow Wiring Diagram

1. Where can I find the wiring diagram for my Meyer plow?

The wiring diagram is typically found in your owner’s manual. If you don’t have a physical copy, search online using your Meyer plow model number and “wiring diagram” or “manual.” Meyer’s official website and snow plow forums are also excellent resources.

2. What tools do I need for wiring a Meyer plow?

You’ll need basic tools like a wire stripper/crimper, pliers, screwdrivers, a multimeter (for testing continuity and voltage), wire connectors (butt connectors, ring terminals, etc.), wire ties, and possibly a heat gun for heat shrink tubing.

3. What gauge wire should I use for my Meyer plow?

The correct wire gauge is specified in your Meyer plow wiring diagram. Using the correct gauge is crucial for proper current flow and preventing overheating. The gauge will depend on the specific circuit and the amperage draw of the component.

4. How do I protect the wiring from the elements?

Use weather-resistant connectors, dielectric grease on connections, and route the wiring in a way that minimizes exposure to snow, ice, and road salt. Consider using wire loom or split loom tubing to protect the wires from abrasion.

5. What should I do if I’m not comfortable wiring the plow myself?

If you’re not comfortable with electrical work, it’s best to consult a qualified mechanic or snow plow specialist. They have the expertise and tools to ensure the wiring is done correctly and safely.